SCIENTIFIC ENGINEERING

Solving, correcting, and preventing structural problems. From design and thermal, stress, vibration and fatigue analysis to materials/ metallurgical troubleshooting, failure analysis, and repair – using “hands on” engineering, we offer expertise to help you solve your technical challenges.

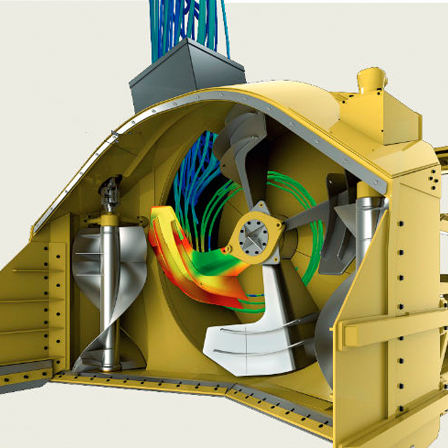

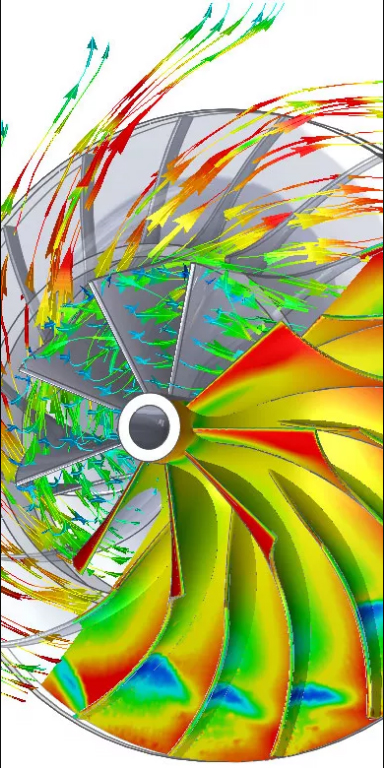

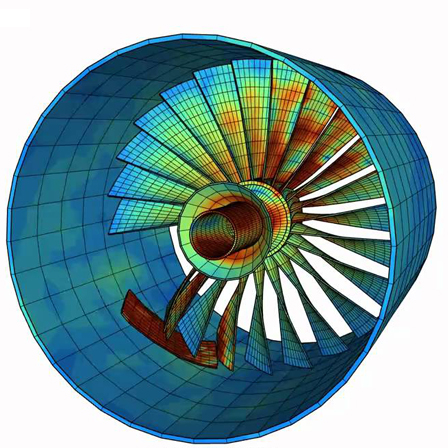

CFD ANALYSIS SERVICES​

We Conduct Simulation & Modeling, Aimed At Helping Engineers Improve Product Quality, Reduce Carbon Footprints, And Improve Product Efficiency At Reduced Costs. We Proficiently Provide CFD Analysis Services For Steady And Transient Flows, Dispersed Multi-phase Flows, Multiple Rotation Zones, Chemical Reactions, Heat Transfer (including Convection, Conduction And Radiation), Incompressible And Compressible Flows, Free Surface Flows And Cavitation, Multiple Streams, Etc.

Our CFD Consultants Are Also Highly Experienced In A Variety Of Industrial Applications Including Biomedical Devices, Electronic Cooling, Under-hood Automotive, Aircraft And Automotive Cabins, Chemical Mixing Tanks, Waste Water Management, Residential And Commercial HVAC, And Wind Loads On Buildings And Oil Tanks.

We Can Solve Any Type Of Simple To Complex Challenges Associated With Fluid Flows And Mechanics. Our Team Is Equipped With The Latest Pre-processing Tools And CFD Software Like OpenFOAM, HyperMesh, ANSYS Fluent, ANSYS DesignModeler/ Meshing, STAR-CCM+, Abaqus/CFD.

- Aerodynamic Analysis

It Encompasses Wind Turbine Blade Design, Vortex Shedding, HVAC Applications, Wind-farm Analysis, And Airborne Particle Transport. - Combustion Analysis

Our Offerings Include Species Distribution, Elemental Analysis, Flame Analysis, Emission Analysis, And Mixing Analysis. - Heat Transfer Analysis

Heat Transfer Modeling, Heat Transfer Simulation, Heat Exchanger Analysis, And Hot Spot Analysis, Heat Sink Analysis. - Multiphase Flow Analysis

Extends Free Surface Flows, Fuel Injection Design & Optimization, Mixed Species & Reacting Flows, Particulate Tracking & Concentration, And Fluid Spray Design & Optimization. - Turbomachinery Analysis

Envisages Cavitation’s Modeling, Blade Design And Analysis To Conjugate Heat Transfer Analysis.

FEA ANALYSIS SERVICES

We collaborate with design engineers to evaluate product design right from early design stages and minimize prototyping trials.

Our FEA specialists provide key insights on the product behavior and constraints that lead to possible pre-mature failure. Additionally, we deliver design optimization solutions for existing products and help reduce resource utilization while keeping product designs efficient.

Services Offerings

- Static & Dynamic Structural Analysis

- Coupled Field Analysis

- Fatigue Analysis

- Thermal Analysis

- Vibration Analysis

Our expertise in FE based simulations has provided us the opportunity to develop potential clients from Automotive, Aerospace, Oil & Gas and Heavy Engineering domains. We have been a strategic partner for major T1 and OEM part manufacturers as well as industry leading engineering organizations across the globe.

We have served as crucial engineering consulting company through a team of qualified FEA specialists, mechanical engineers, CAD professionals and industry experts. Additionally, we use industry leading software technologies and high performance workstations to handle complex engineering projects and large volumes of data with least turnaround time.