REVERSE ENGINEERING

Our team has a cumulative experience of over 12 years in building engineering drawings, 3D and 2D models, and digitization which is a clear distinction over other reverse engineering companies.

Our reverse engineering services include:

- Detailed dimensional/geometric analysis

- Material and surface analysis

- Electronic and Electrical analysis

- Quality control inspection

- Manufacturability analysis

- Prototyping

- Design for Manufacturing and Assembly (DFMA) analysis

- 2D and 3D drawings

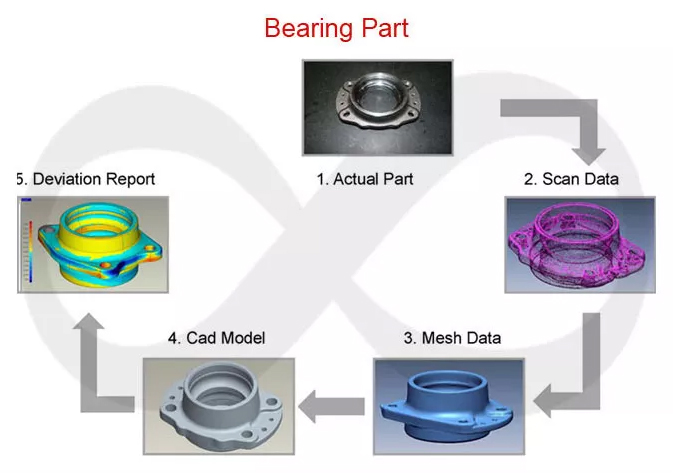

HOW DO WE DO THIS​

Apart From Traditional Manual Geometric Designs, We Utilize The Following Techniques To Offer Cost-effective Reverse Engineering Services To Our Clients:

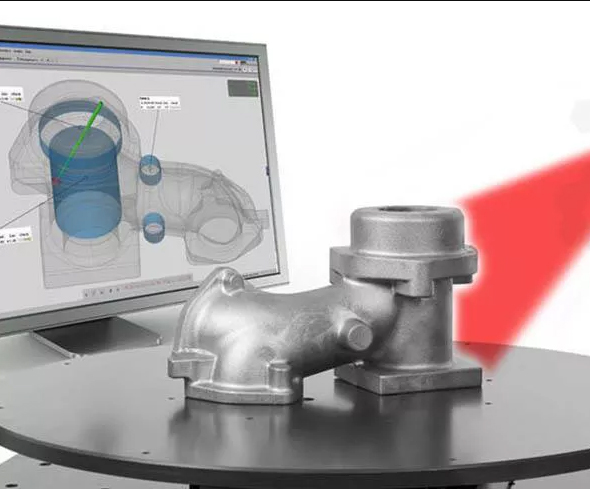

- Non-contact Inspection

- Coordinate Measuring Machine (CMM) Scanning

- Portable CMM Scanning

- Full Contact CMM Scanning

- 3D Laser Scanning

- CGI Scanning

- Computer Aided Inspection (CAI) And Computer Aided Verification (CAV)

After Scanning Of Each And Every Part Of The Product, Detailed 2D And 3D Drawing Are Created. Read Our Article Which Highlights The Benefits Of 3D Laser Scanning In Reverse Engineering. Our Experts Also Offer Suggestions For Improvisation Of The Design, Quality, And Manufacturability Of Any Given Physical Product.